|

Curtis 5

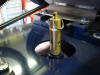

HP, 3-Cylinder, 80-Gallon Air Compressor

Well, about 15

months or so ago I bought a used Curtis 80-gallon horizontal air

compressor. It had a 5HP, 3-phase motor and a 3-cylinder, Model

E-50, 2-stage pump air compressor pump. It ran but made a

knocking sound and I suspected a high pressure cylinder bearing

was bad but definitely worth a 90 minute drive and $75 price

negotiated down from $200.

Once I got it home it received a thorough washing with Bleache-White®

cleaner and soap and water so I could inspect it closer

and to make the tear-down process easier.

Over the course of the next year I completely restored the

compressor to better-than-new condition and performance. The

high pressure piston wrist pin bushing on the connecting rod

was, in fact, worn bad when I bought it so I ordered a new wrist

pin, piston & rod. I couldn't buy just the wrist pin roller

bearing for the rod so I had to order the complete rod assembly.

I ordered an overhaul kit with brand new seals, gaskets. rings,

bearings...everything to completely overhaul the entire system.

I

also ordered a real 5HP Baldor motor (Model L1430T, Frame 184,

1.125" arbor shaft, 21 FLA, 1740 rpm) so when operating the pump

is churning at approximately 923 rpm and cranking out 17.4 SCFM

@ 175 psi. I added a new 5HP magnetic starter with new 8/3 SOOJ

cable for the electrical system. The magnetic starter has an

auxiliary 230V relay that I wired into the electrical system to

minimize current across the pressure switch contacts. The

pressure switch still acts as a switch but does not carry the

full load of the motor through the contacts. The auxiliary relay

also provides me with provisions for the LED indicator. This

illuminates whenever the compressor is ON (even though it may

not be running because ultimate pressure has been reached and

the system is in a standby mode.

I fabricated an hour meter for the compressor and also a rather

complex looking (yet simple in theory of operation) air

cooler/moisture separation system that yields me virtually dry

air. You will see many non-standard features that I designed and

incorporated into my compressor, so please do not hesitate to

contact me

should you have any questions..

Engine Hoist & Engine Stand

One major tool tandem that I was going to need for the

restoration was an engine hoist and engine stand. I wanted an engine hoist that had sufficient height

and boom length to work on my medium duty trucks and also something strong enough to handle heavy

lifting operations. I found some for sale but they were either too expensive or the quality was less

than acceptable given my application, so I built a matching set. I used 3" x 3/16" square stock for

the main parts and 2.5" x 3/16" square stock for the inner adjustable pieces, such as the leg

extensions and extendable boom. All pins and reinforcing plates are stainless steel. The casters are

industrial type (ball bearing swivel, neoprene wheels with a solid steel center hub) that I got for

free. The whole unit was welded using a Miller TIG welder.

Tow Bar

Well, I had some left over steel from my engine

hoist and engine stand so I decided to fabricate this handy tow bar for my 1964 & 1966 C60s. I made it

such that it will easily bolt directly onto the bumper flanges that are riveted to the frame. I don't

plan on towing my trucks over the road. The tow bar was fabricated so I can move my trucks around the

yard and in and out of the garage when I'm working on them.

Oxyacetylene Torches

I recently

purchased a nice set of torches for working on my trucks. The

regulators and torches are from

Victor Super-Range

II and the whole setup was

purchased from my regional

AirGas distributor. I really like

the cart as it has a nice storage tray for all the tips,

striker and goggles and has large pneumatic tires so it's easy

to roll around on uneven surfaces.

Storage Sheds

Here are some

pictures of the sheds that I custom built last year. I cleared

and leveled the area, build the sheds and then placed weed

block and stone around for landscaping. OK, so my sheds are

not exactly what you would call a "tool", but I use them

indirectly during the restoration process. The first one

closest to the tree is setup with wire metro rack shelves and

I use those to store all the small parts that come off my 1964

Chevy C60 during the

disassembly process. There is also

adequate floor space for the large items such as the fenders,

inner fender wells, bumper, etc. The second one, closest to my

1966 Chevy C60 parts truck,

houses infrequently used and larger tools as well as my Honda

Foreman Rubicon 4x4 ATV.

San-Blast Pressurized

Sand Blaster

I'm supposed to be

restoring my dump truck and not my tools; however, some

times you have to get the tools in good operating condition

before you can use them. Thus was the case with a San-Blast

pressurized sand blasting system my brother in Massachusetts

shipped me back in the Fall of 2005. It'll take a 50 pound

bag of media but it was in pretty tough shape after years of

use. Be that as it may, given the cost of a new system

versus a little overhaul of a free system...well...you get

the idea.

Upon receipt the

pressure gauge was broken, the hoses were cracked from dry

rot and the tank was rusted and covered with overspray from

years of sitting in a paint booth. I pulled the plumbing

system apart and what wasn't corroded was pretty worn out.

Once it was stripped down I took my pneumatic sander and

cleaned up the tank to bare metal and then gave it a hand

sanding with 240 grit Wet-or-Dry sandpaper. Once the tank

was primed and painted I went to my local

Home Depot and picked up all new parts for the plumbing

system. The re-assembly actually took a bit longer because I

didn't want to paint the new valves (I know, I know...) but

once the paint on the sub-assemblies dried I put it all

together and it looks good as new.

Transmission Adapter

In order to

restore the New Process 540C 5-speed transmission I

fabricated an adapter that bolts onto the side-mounted PTO

opening of the transmission case. Using the PTO housing as a

template I fabricated a plate that would bolt onto the case

in place of the PTO assembly. Next I turned down a piece of

1½" cold rolled steel solid round stock to 1.460" so that it

would fit into the engine stand above. After achieving the

correct diameter one end was cut at approximately 15º and a

hole was drilled in the opposite end to facilitate a handle.

The end with the handle was drilled and tapped to accept a

½" x 13 bolt to secure the handle. The shaft was then welded

to the adapter plate to finish off the fabrication. The

whole thing was fabricated with scrap stock that I had saved

during the removal of the flatbed and lift gate from my

1966 Chevy C60

parts truck.

Back

to top |