|

The

Heater Assembly

The Deluxe Heater

components are located on each side of the firewall. The blower

assembly and the core and valve assembly are located in the core

case on the engine side of the firewall. The distributor duct,

with the defroster equipment and the resistor assembly are

located on the passenger side of the firewall. All diverter

doors are located within the distributor. Air is drawn from the

cowl vent plenum chamber, down through the heater core and is

pulled by the blower, through the blower and into the

distributor within the cab of the vehicle. The thermostatic

valve is a manually set temperature control to limit core and

outlet air temperature. The image below illustrates the heater

assembly per the 1963 Chevrolet Truck Shop Manual.

Cleaning and Painting

Once completely

disassembled all parts were media blasted and wiped down with a

clean lint-free cloth and isopropyl alcohol to remove any media

dust.

As with the

Bendix Hydrovac I

elected to use Rustoleum from the can; a product readily

available at most hardware stores and home centers. The primer

was a standard light grey and I chose a gloss black for the

final color. Given the inherent porosity of spray can paint, I

applied 3-4 light coats of primer to each piece, allowing

approximately 15 minutes between coats to allow the previous

coat to partially dry and also to prevent running. Once the

final coat was applied the pieces were allowed to dry for a

minimum of 48 hours. Each piece was then lightly sanded using

dry #400 wet-or-dry sandpaper and wiped down with a clean dry

cloth. The color coats were applied in the same manner as

mentioned above.

Each part received 3

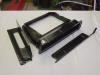

coats of gloss black paint. The images below show the main

heater assembly parts following the painting.

Parts Order

I checked with my

local NAPA store and they indicated they had a heater core for

my truck. The image below show the old heater core and the new

NAPA heater core. At first glance they appear to be the same.

The core dimensions are identical as are the inlet and outlet

tube diameters; however, the spacing between the tubes was too

close. While the heater core fit into the heater box just fine,

the plenum did not fit. The tubes would not clear the 2 angled

slots in the plenum unless the plenum was filed to increase the

size of the slot.

After I brought the

heater core back to NAPA for a refund I sent a detailed e-mail

to Classic Parts

customer service department explaining the dilemma. I provided

dimensions and also explained why the NAPA version would not fit

for my application. The next day I received an e-mail indicating

that the Classic Parts heater core would work for my truck. So,

in addition to the

heater gasket set,

heater motor, and

heater fan, I also ordered the

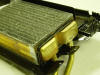

heater core. The images below show the original heater core

and the Classic Parts heater core.

Note that the diameter of both the inlet and outlet tubes is the

same, and that only the end of one tube is flared to 3/4".

Because of this, the heater core fit perfectly in the 2 angled

slots mentioned above. It should also be noted that the 3/4"

hose from the water pump connects to the upper 3/4" tube on the

heater core and the 5/8" hose from the thermostat housing

connects to the lower 5/8" tube on the heater core. The customer

service I received from

Classic Parts was excellent as was the quality of the

products I purchased from them.

Assembly

Reassembling the heater was pretty simple. I had purchased new

screws for the whole project at the local hardware store and

primed and painted them as well. Below are some images of the

heater assembly in various stages of reassembly and also the

completed project.

Back to top |